- About

- Products

-

-

- 12|34® Formula

ARMITE-MIL-PRF-81308H - Technical Petrolatum

ARMITE- VV-P-236A(2)N3 - Molybdenum Disulfide Petrolatum

ARMITE- MIL-PRF-83483E - Graphite Petrolatum

ARMITE- SAE-AMS-2518D - Zinc Dust Petrolatum

ARMITE- A-A-59313 - Boeing Anti-Seize Compound

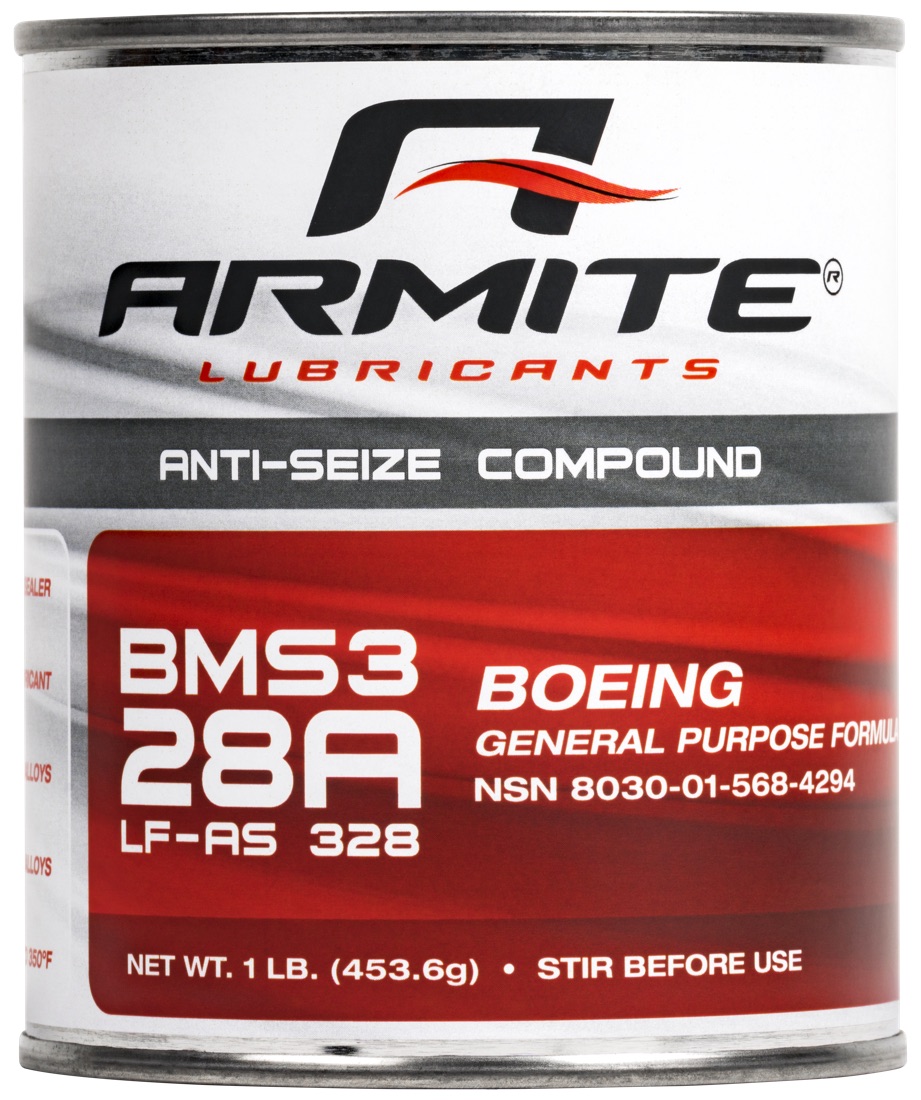

ARMITE- BMS3-28 (LF-AS 328) - MIL907

ARMITE- Meets MIL-PRF-907F - ARMITE- 1001 Rust Penetrant

MIL-PRF-680C Type II

- 12|34® Formula

-

- Spec Materials

- Industries

- Distributors

MENUMENU