Molybdenum Disulfide, with its excellent lubricity and high load capacity, is particularly suitable for use on aircraft spark plugs and threaded fasteners and fittings at temperatures below 800°F.

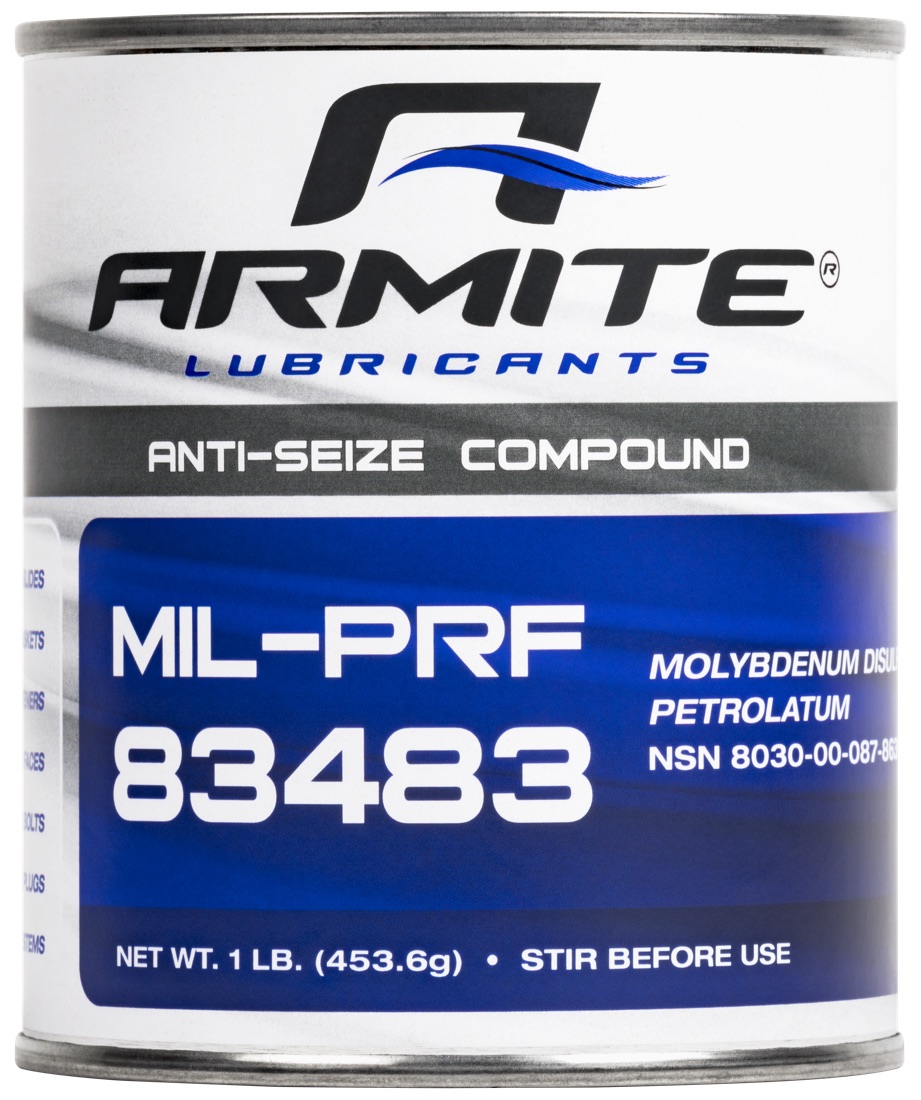

Armite Lubricants is a company that takes pride in the traditional approach to manufacturing its MOLY-Blue anti-seize compound, which is designed to meet the performance requirements of MIL-PRF-83483 Revision E. By using a hands-on approach to production, Armite is able to ensure the quality and consistency of its products, which is critical in ensuring the reliability and longevity of aerospace systems and components.

The personal care and attention to detail provided by Armite’s highly skilled “Chef” is a unique approach to production that sets the company apart from others that rely on industrial automated machinery. By using hands-on production methods, Armite is able to monitor every aspect of the production process and make adjustments as necessary to ensure that its products meet the high standards of quality required for use in aerospace applications.

In addition to hands-on production, Armite also performs rigorous lab testing on its MOLY-Blue anti-seize compound to ensure that it meets the performance requirements of MIL-PRF-83483 Revision E. This testing helps to validate the product’s quality and performance and provides assurance to customers that the product will perform as expected in aerospace applications.

Some other suggested applications include gaskets, valve stems, fasteners, spark plugs, etc.

Note: Products listed are suggestions. The information on this site will not replace your testing and evaluation procedures. Ultimate product selection should be based on your test results and the specific performance requirements.

Available in:

8 oz. tube, NSN 8030-00-243-3285

1 lb. can, NSN 8030-00-087-8630

1.75 lb. can, no NSN

35 lb. pail, no NSN

500 lb. drum, no NSN

Typical Characteristics:

Color: Dark grey

Physical State: Semi-solid paste

NLGI Grade: 2-4 approx.

Penetration: 170-260

Specific Gravity: 1.44

Flash Point: 360°F (182°C)

Auto Ignition Point: >500°F (>260°C)

Additive type: MoS2

Service Range: -65°F to 800°F (-54°C to 426°C)