- Anti-Corrosion Quality – MIL907 not only has a high corrosion resistance but also prevents oxidation and corrosion in the materials to which it is applied. This quality makes it a standard for all-around use in chemical plants and refineries.

- Anti-Seize and High-Temperature Qualities – The compound remains an effective anti-seize compound, even to the fusing or melting point of the surrounding metals. The hydrocarbon vehicle melts away between 600°F to 700°F leaving only the pure lead, which becomes liquid at about the same temperature. On cooling, the lead solidifies as a fine metallic ash and still retains its lubricating and sealing qualities. Recommended uses include steam and gas turbines, refinery units, boilers, railroads and aircraft.

- Low-Temperature Use – The compound forms an effective seal for equipment handling liquid nitrogen at -350°F. It is recommended for pipe sealing applications at temperatures of -100°F.

- High-Pressure Applications – Increasing pressure causes lead particles to pack more closely, strengthening the seal. MIL907 has tested up to 100,000 PSI hydraulic fluid lines.

- Anti-Seize (Metal to Metal) – MIL907 prevents a corrosion weld between metal-to-metal surfaces. This feature is important from the standpoint of maintenance of heavy industrial equipment.

- Anti-Galling or Anti-Freezing – The compound forms a thin, pure-lead coat on metal while filling all voids and smoothing the surface. Friction is greatly reduced and less torque is needed for assembly and disassembly. Because the joined metals are isolated from moisture and oxygen, deterioration by galvanic action is impossible. In the same manner, hydrogen embrittlement is prevented.

- MIL907 is particularly useful for materials that gall easily, such as aluminum and stainless steel.

- Lubricating Qualities – MIL907 is valuable as a lubricant in many tapping, machining, and metal-forming jobs. It is not recommended as a bearing lubricant except for very loose journal bearings, as MIL907’s plating action will freeze close-tolerance bearings.

General Applications:

• Threads on steel nuts, studs, bolts, and other mating surfaces including superheated steam installations

• Threaded connections

• Pump housings

• Flanges

• Studs

• Exhaust manifold bolts

• Compressor heads

• Autoclaves

• Lathe centers, etc

• Steam and gas turbines

• Refinery units & boilers

• Fasteners

• Etc. (for other applications/uses consult a properly licensed or trained mechanic or another qualified technician)

*Always consult with a licensed, qualified, or trained mechanic or another qualified technician for proper use

Note: Products listed are suggestions. The information on this site will not replace your testing and evaluation procedures. Ultimate product selection should be based on your test results and the specific performance requirements.

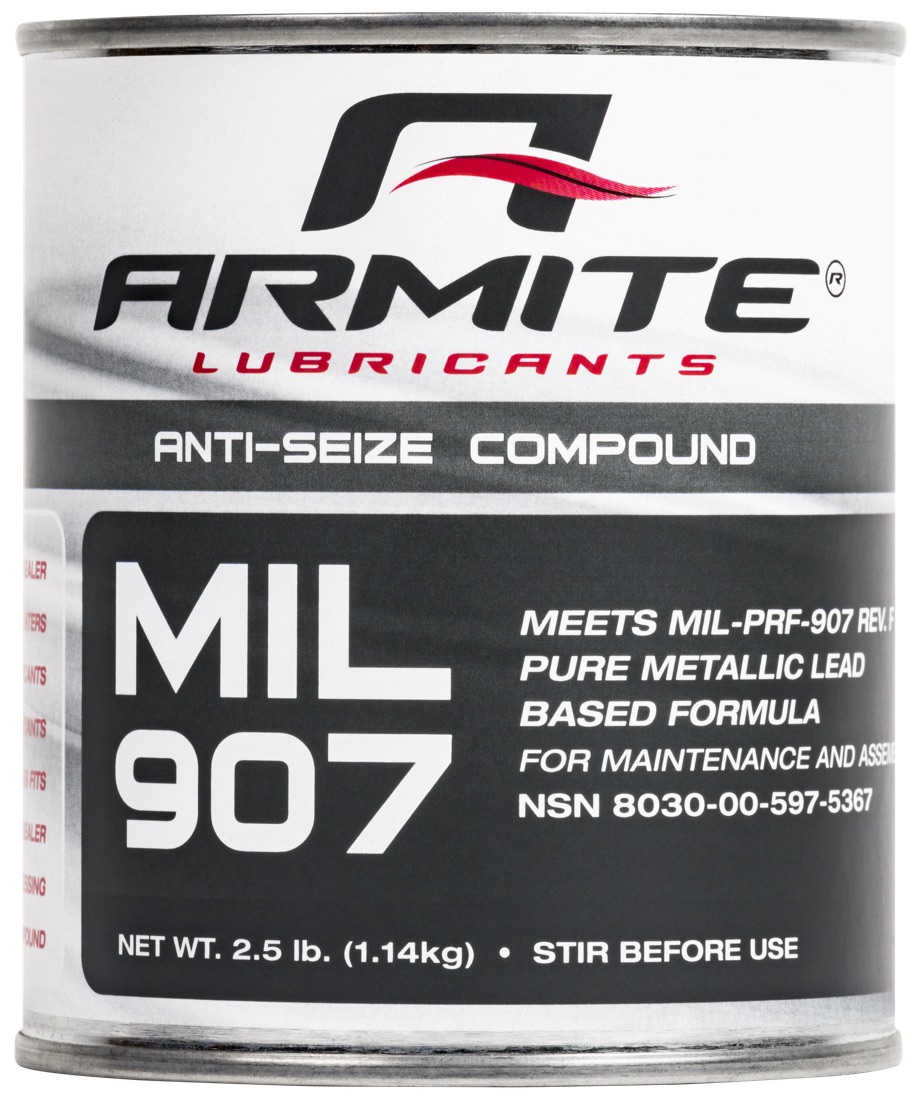

Available in:

4 oz. can, NSN 8030-00-059-2761

1 lb. plain top can, NSN 8030-00-251-3980

1 lb. brush top can, NSN 8030-01-607-8134

2.5 lb. can, NSN 8030-00-597-5367

5 lb. can, NSN 8030-00-286-5453

50 lb. pail, no NSN

Typical Characteristics:

Color: Dark grey

Physical State: Semi-solid paste

NLGI Grade: 2-4 approx.

Specific Gravity: 1.93

Flash Point: 404°F (206°C)

Additive type: Mineralized Lead

Service Range: -350°F to 2987°F (-212°C to 1641°C)